LED technology is one of the emerging technologies that is taking over traditional and old-style lighting bulbs. From bulbs to torches, you might have heard of LED headlights, however, in the automotive industry, LED lights are a new king.

Over time the applicability and functionality of LED headlight bulbs have been greatly improvised and improved. In this article, we are going to take an in-depth look at LED headlight bulbs from an automotive industry perspective.

It might be surprising, that many people are not well-informed about LED headlight bulbs, their vital role in cars, and where to get them from.

LED headlight bulbs are used in vehicle headlamps, tail lights, indicators or side lights, and road bumper reflectors.

When the abovementioned headlights stepped into the market, they were only used for top-in-the-line-cars models. However, with the passage of time and their high demand, they are also now being used in base-model and mid-variant cars or vehicles.

Before we dig deeper and get into a detailed discussion, we must discuss their benefits of them that will translate into the reasons people are inclined toward LED lights.

Read more: Do you know the basic knowledge of car LED headlights?

As we have mentioned before that led headlight bulbs are rapidly becoming well known around the globe. The trends are changing and people are becoming more aware of the products, especially in those ways where the energy consumption is less. The reason behind this can be explained using some interesting facts that will help you in understanding their impotence in your car. Let’s have a look at them.

Read more: What are the advantages of LED headlights compared to laser headlights?

There is a wide variety of LED headlight bulbs when it comes to the automotive industry. The question is always LED headlight bulbs vs halogen. To name the most common headlight bulbs used in cars are halogen, LED, Xenon, and Laser. In states like the USA, halogen lights have been the standard for car manufacturers since 1970. However, as the trends are changing now, car manufacturers are taking a shift and are inclined towards using LED headlight bulbs for vehicles whether trucks or cars.

Not only car manufacturers are using but the buyers or consumers also prefer LED headlight bulbs to halogen bulbs. The answer is LED headlight bulbs for the car because anyway, the car owners are getting their LED headlight changed. If their headlight bulbs are manufactured of halogen, then they get LED headlight bulbs from aftermarket to give their car a better experience.

To dig deeper, we are going to list a few pros of switching from halogen to LED headlight bulbs. This will help you in understanding the shift in the automotive industry towards LED bulbs from halogen bulbs in cars.

Read more: How to buy it correctly when halogen car headlight is modified to LED car headlight?

Energy efficiency is an integral part of the working of the car and battery alternator. LED headlamps are manufactured in a way that they consume less battery as compared to halogen bulbs. To be more precise and statistical about this, 85% less energy consumption is said to be the main feature of LED headlight bulbs.

In case you accidentally leave your car’s halogen headlight bulbs switched on, the strain on the battery alternator will be enough to slow down the working of your vehicle’s battery. In the case of LED headlight bulbs, the strain on the battery is least or we can say unaffected.

Now consumers or buyers prefer LED-made headlamps as they are more beneficial on the inside working or battery and engine of the automotive vehicle. They produce more energy, fewer lumens emission, and low battery consumption than the other types of headlight bulbs for cars.

Good quality can outweigh the pang of higher prices, right?

Even though halogen headlight bulbs are not pricey as LED headlights but here is a catch; the former has a shorter life span. The halogen headlights have a life span of 1000 to 6000 hours whereas the LED headlamps have around 25k to 30k hours and some even have around 50k hours. Isn’t this a great deal?

Uninterrupted vehicle lighting is one of the catchy attributes that LED bulbs possess. You might be thinking that why or how uninterrupted lighting is better.

The answer to the above-written question is that it is the most suitable headlights for everyone however for the following it’s the best investment they can ever do for their car:

LED headlight bulbs for cars are extremely durable and can last for nearly ten years. They have high-quality materials that are shatter resistant and less prone to damage or breakage. They perform admirably in adverse weather conditions. LED headlights are designed and produced to bear road vibrations as well as other disruptions.

It is important for the LED headlights to produce a concentrated amount of heat so that it does not break. They generate concentrated heat that is cool enough to touch. As a result, the plastic components surrounding them are shielded from extreme heat.

LED headlamps for cars are not as dirt or debris sensitive as halogen headlight bulbs are. It is underpinned by the fact that if you need to change your halogen headlights one has to be extremely careful about the debris. If there is debris or grease during the headlight replacement then there are higher chances that the heat production through halogen lights would cause the lights to burst or might reduce the longevity of the headlamps.

In LED headlights, the case is entirely the opposite. You can easily change your LED headlights without being too much conscious of debris, grease, or anything like that.

The aftermarket is filled with an abundance of LED headlights for automotive but the quality is lacking. To make sure that quality is up to the mark, you need to know the anatomy of LED headlights and what components are integral to the top-notch market quality for LED headlights. Let’s have a look at the main features of LED headlight bulbs for your car.

To enlist, here are the 4 main components of the Light emitting diode (LED) headlamps:

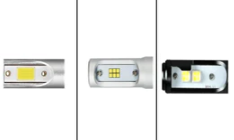

LED chips make the integral system of the LED headlight bulbs. The functioning of the LED chips in the headlamps is the conversion of the electrical energy into light energy so it can emit light from each diode. However, there are certain types of LED headlight chips . Let’s have a look at them

Chip on board is one of the types of LED chips used in the headlight bulb of the automotive industry. The main advantage of using this in your car headlight is that it is well illuminating at a reasonable price. However, there is a con also attached to it: It does not have a longer life span and only works well for the lower operating machines or vehicles.

When it comes to the functionality of the chip scale package or CSP it does not differ a lot from COB. It also bright well and is sharp however the price range is moderate.

However, the main disadvantage of this chip is It produces high-intensity light yet does not have a good mechanism for dissipating heat – for the safety of headlight bulbs.

This is one of the well-known chips as it delivers high lumen density from the headlamp of the car with a higher light efficiency. However, it does not follow a good beam pattern which can affect the vision.

As the name suggests, the lamp body works for the aesthetic value of the headlight bulb. But it is not all that it does – there is more to it.

The lamp body also plays an important role in process of heat dissipation. There are different kinds of lamp bodies and they can be differentiated by assessing material, the thickness of the material, and the area it has for dissipating heat.

It must be noted that the material of the lamp body is directly linked with the battery and the longevity of the life span of the headlight bulb. If the material does good heat dissipation, then the lifespan of the lamp body will increase and will get better substantially. Extruded aluminum alloy 6063 should be used for LED headlights with improved cooling management. Furthermore, LED bulbs paired with various cooling methods can boost heat dissipation capacity.

After the led chip, the main role of the drives LED headlight bulbs is a circuit board that is also known synonymously as a driver. In the automotive industry of headlight bulbs, they are considered the most crucial part to fetch a high functionality of the LED light lamp.

The main benefits of the circuit board are that they prevent the headlight bulbs from getting shattered or damaged which can be done through the variation of the voltages. It optimizes heart production and keeps the substantial damage to cars at bay.

The main components of the driver are:

At SKLED TECH, we use advanced and high-end technological machines to ensure accurate welding processes, cleanliness, and top-notch quality for our clients.

The purpose of the heat sink, as we mentioned earlier about, is heat dissipation. In the heat sink, for the dissipation of heat in LED headlights, three components are very significant. They are:

To explain it further, here is useful information for the readers and car enthusiasts:

The copper tape cooling and pure aluminum cooling limit the cooling capacity for LED headlights. If the car manufacturers use pure aluminum cooling, then it is recommended to keep the size big for efficient heat energy dissipation but that can lead to problems in placing LED headlight bulbs in your car.

The best method, after experimenting and testing, placing a fan inside the heat sink would be the most beneficial and workable solution with the most energy production.

For processes like conduction, convection, and radiation – placing a fan inside the heat sink works too well.

The working of automotive headlight bulbs is linked to two main parts: the first one is semiconducting material that transmits the energy and the second one is the ignition or relay. As soon as that car starts, the headlight bulbs are automatically turned on as per their function.

When current passes through them, illuminate by driving energy from the car’s battery. With the semiconducting material gets current, it starts to flow from the cathode to the anode so that the material with conductivity ranging between metal and rubber gets the current. As soon as the semiconductor gets energy, it starts to emit photons and the headlight’s bulbs illuminate.

This is one of the most frequently asked questions because buyers are often confused and want the right product when it comes to quality.

So, to save you time, here are some important specifications or specs of LED automotive headlight bulbs that you should consider before buying:

Let’s look into each one of them step by step:

The pattern is what you will see on the road when the headlight bulbs will illuminate.

The beam of a pattern of the headlight bulbs defines the angle at which the bulbs will case their lights. As per the safety regulations of the Society of Automotive Engineers (SAE) – globally working – they say that there must be a certain angle to which the headlight bulbs should be adjusted.

The perfect angle for the headlight is that from the center of the automotive headlight bulb should shine at the exact height of 36 inches (and there should not be any change in measurements or more than that). As a precaution, check with the car’s company in order to make sure that it follows the regulation of SAE.

For setting the intensity and color, one must understand the word ‘lux’.

Lux is the measurement of the light that reflects in a small area and it is measured in lumens per square meter.

To check if the lux is top-notch quality or not, there is only one condition.

That one condition is that if the light of LED headlight bulbs spreads evenly throughout the beam, then it is the right one for you and your car. To write in layman’s terms, the lightning should be brighter from some sides and darker or lightened from the other side.

Talking about the color now, there is a variety of colors in headlight bulbs.

It is entirely over your discretion about what color and tints you want for the headlight bulb of the car. You can opt for a cooler tone, warmer tone, or neutral tone.

It is up to you.

Not every headlight bulb fits every vehicle.

Therefore, one must understand the headlight bulb that fits their vehicle. Fitment is the most important factor as this will make your headlights the right go you need. If you want to know about the headlight bulb fitment, you can read the information written on the bulb, read the vehicle handbook, or directly contact the manufacturer.

At SKLED TECH, you can get the headlight bulb for your car that fits your car appropriately.

Lifetime is what you pay for. There is no doubt that LED headlight bulbs for the automotive industry are expensive as compared to halogen or xenon bulbs but LED headlight bulbs provide you with the quality and durability that is hard to find elsewhere.

As a matter of fact, LED headlight bulbs have a longer life span ranging from 30 thousand hours to 50 thousand hours. Buying an expensive LED headlight will have longer life as compared to the cheaper one.

So, now you know and the decision is yours!

In the automotive industry with special reference to LED headlight bulbs, the CANBUS system is important and works in intelligence. In the LED automotive headlight bulbs, some bulbs are CANBUS-free. CANBUS-free bulbs are those that have resistors attached to the internal and external sides. The LED headlight bulbs must be CANBUS error free which shows the headlight bulb is working fine and has no danger of low energy or malfunctioning. Therefore, always have the CANBUS testing before you make the purchase.

Read more: How CANBUS Modules work with LED Headlight Bulbs

If you are not clear about this, then there is a higher chance that you might get the wrong lamp body for your car’s headlight bulbs. Being one of the most-asked questions, we decided to answer this question in this investigative guide to understand LED headlight bulbs. We mentioned earlier the lamp body and its interlinking with heat dissipation along with battery life. The answer to this question is:

To clarify the good heat dissipation capability of the lamp body, here are a few factors to consider and test while buying one:

The greater loads the weight of the same volume of the headlamp body, the greater the density, and the stronger the heat dissipation.

The greater the thickness of the lamp body, the superior thermal dissipation. Hence, better working and efficient battery life.

The relatively large the area, the better the heat dissipation; an optimum heat sink design will speed up the flow of air, resulting in improved cooling for the LED headlight bulb.

This is another one of the most asked questions when it comes to LED headlight bulbs for the automotive industry.

After testing and experimenting, LED headlight bulbs are not omnidirectional which means that they do not illuminate or spread light from all sides. Rather, they spread light only from the diode in a straight direction. However, as we have discussed earlier, LED headlight bulbs for cars are more illuminating than other kinds of bulbs such as incandescent or halogen ones. Here is one thing that we recommend is that the alignment of LED headlight bulbs must be done properly to get a clear vision of the rod and vehicles ahead.

Also, in some cases, if you get new suspensions in the car or get new tires that change the height of the car, then the position of LED headlight bulbs must also be reoriented. It is necessary to note that the placement of the headlight bulbs must be center aligned. Why? Because placing them a bit to the height would make others blind while placing them too low will not give a clear vision of the road. Hence, get the position right of the led bulbs for automotive for your car.

Quality is one of the most important factors for producing top-notch materials LED bulbs for automotive vehicle parts. Ensuring the quality of LED bulbs, tubes, and lighting fixtures translate into providing rigorous quality control with A/B testing and control equipment standards.

In this part, we are going to discuss the types of testing conducted on LED headlamps, lighting fixtures, and light tubes.

For incoming quality control, all the products for manufacturing are tested properly to ensure that the quality is A+. For every material for the automotive LED headlight bulbs, there are different requirements for quality assurance. Incoming quality control is the first step in providing clients with the quality we at SKLEDTECH promise for.

The second test for ensuring the quality of the LED headlights for cars is in-process quality control. For this test, we inspect the process before the manufacturing process is completed and the prototype of the automotive vehicle is ready to go for testing of final quality control. This step is vital for the manufacturers as it gives them assurance of the quality of materials used in the process. Moreover, it checks final product will fulfill all requirements of the criteria ‘high-quality’.

The last step of testing the quality of LED automotive headlight bulbs is final quality control testing. In this process, we inspect the product that has been manufactured and are ready for the comprehensive testing of the headlight bulbs before they are ready to sell and put into storage.

These three tests are done to maintain the quality of the product we sell. After undergoing this extensive process, we claim the quality to our clients around the globe.

At SKLED Tech, we ensure quality by doing three different testing to provide our clients with the remarkable quality we have promised.

Apart from the three-step testing, there are other types of tests that are done to ensure the quality of the LED headlights.

To enlist them, let’s have a look at the following list:

The integrating sphere is also known synonymously as the Ulbricht sphere which is named after the inventor of the testing instrument. In automotive LED headlight bulbs, there is a need to be extremely reliable measurements for calculating the range, luminous flux, and radiant power. Ergo, an integrating sphere is used for testing the automotive LED headlights.

As a matter of fact, the integrating sphere is only a part of the larger system for the overall measuring instrument as it includes a detector – whether a photometer or spectrometer – to measure or calculate the light beam intensity.

For measuring the luminous flux and power range, integrating the sphere with a photometer was used. With the passage of time, photometry was introduced to calculate the incandescent light spectrum that is continuously emitted from the incandescent lights or bulbs,

Photometry helps measure the energy efficiency and average life of the lamps or LED headlight along with the spatial distribution of the light. In this device, there is an optimal correction filter (V, λ) that fits the light sensitivity of the device in relation to the human eyes. It helps in understanding how the LED headlight bulb will be perceived and viewed by the naked human eye.

This is one of the most important pieces of equipment for ensuring the quality and life span of Light emitting diode headlight bulbs aka LED headlight bulbs.

In the automotive industry and LED bulbs, the major nuisance occurs due to some improper welding process, wrong temperature, or extremely prolonged soldering time. To keep the malfunctions at bay, the aging testing rack is conducted for the quality assurance of the product.

To define the LED bulbs for automotive aging test rack, we can say:

“A testing procedure conducted to ensure the quality of the LED life span and longevity that meets the requirements of the set criteria.”

To understand the general process of automotive manufacturers, here is the standard process:

The LED aging rack instrument or equipment enables the setup of every necessary process for testing the product such as manufacturers can increase or decrease the frequency, voltages, power, and much more.

Hi-pot testing is the abbreviation for High potential testing. It assures the safety of the product with special reference to ‘electricals safety’.

The high potential testers or high potential testing equipment serves a wide range of capabilities such as giving accurate calculations or low-resistance measurements, calculating low-resistant or high-output calculations for voltages. This testing benefits from testing the ground resistance and ground bond integrity.

The working of Hi-pot testing starts from the step when the conductors apply a high voltage to the chassis of the device being tested or device-under-rest (abbreviated as DUT). In automotive terms, the testing process is also known by the other name i.e., dielectric.

The purpose of performing this test is to ensure that the insulating used on the non-conducting surfaces. Also, it checks whether it is enough to save the surface from sudden shock and can avoid a hazard. For this, the typical calculation for voltages is “2 x (normal operating voltage) + 1000V.”

Vibration testing is for ensuring that the assembly of the LED headlight bulbs and all the parts are proper. It helps in testing that the led headlight bulb fixtures will not sift away from their places and will work properly on bumpy roads or where the vibrations are fast and have a higher frequency.

The Drop test is to check the sturdiness and strength of the material of the LED headlight bulbs. For this type of testing, the height or measurements could vary from product to product. This type of testing is crucial for the clients and product shipment or for those who buy from the online store.

Get the best quote for your car’s LED headlight bulbs at SKLED Tech with competitive pricing and high-quality products.

As we are near to concluding about LED headlight bulbs for cars, LED headlights for jeeps, and other vehicles, we have some points for you to keep in consideration before you make a purchase.

The overlocking chipset in the headlight bulb will make the headlight work excessively and quickly which can lead to hazardous results. In case there is the overclocked chipset, you might get:

Therefore, always buy a LED headlight bulb that is not overlocked but rather a normal one so that you can drive smoothly and have workable headlight bulbs for your car.

If you want to get top-notch quality headlight bulbs for your car and improve the experience of driving, then check LED headlight bulbs for cars at SKLED Tech.

We exclusively are the OEM and ODM Manufactures of innovative LED headlight bulbs with experience of more than 20 years in the Auto Headlight Industry.

Our knowledgeable and expert team works together to bring out high-quality headlight bulbs so that we deliver what we promise.

Get a free quote now by contacting us and have an amazing experience with your car!