How CANBUS Modules work with LED Headlight Bulbs

Does my car have CANBUS?

Modern vehicles use sophisticated electronic systems onboard to control and monitor your vehicle’s headlights. When you replace the stock incandescent light bulbs in your fog lights or headlights you might run into an issue with the vehicle’s lighting computer thinking there is a problem. Back in the old days, the headlight circuit was a simple on/off 12v switch… that is no longer the case! Some vehicles have a standalone computer specifically to control the different lighting functions on the vehicle and it’s programmed to know exactly how a standard light bulb functions. As soon as this specialized computer “sees” something that doesn’t line up with it’s programming it either puts the system into a diagnostic mode or keeps functioning and throws an error.

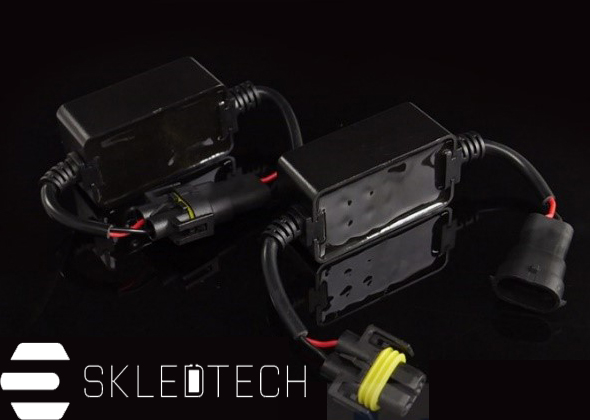

This could happen because the new LED headlight conversion kits will “read” differently than the stock bulbs to your vehicle’s computer. If you have these symptoms consider trying a warning canceller module. It requires no extra modification, and is a simple plug and play connection between the factory vehicle wiring and your LED conversion kit wiring.

When will you need a decoder? When you install LED headlights into your car and have any of the following problems., you may need a decoder.

(1) Bulb flashing when turned on.

(2) Headlight error displayed.

(3) Bulbs stay illuminated after they are turned off.

(4) Abnormally dim light output.

We’ve found that Volkswagen, Ford, Jeep/Chrysler, Mercedes, and vehicles using pulse width modulation (PWM) tend to need CANBUS adaptors the most.

1. Power Monitoring

Some CANBUS systems monitor the current in-rush of the light bulb it’s controlling and when it sees a larger amount of current, or a smaller amount of current, than the original bulb it causes a problem. A CANBUS decoder may be the best option for something like this as it uses capacitance to smooth out the power demands of the new bulb and helps the system adjust to the aftermarket product.

2. Pulse Width Modulation (PWM)

Pulse width modulation, PWM, is a technology to reduce the heat value of halogen bulbs, help the bulbs last longer, and save more power while operating. But LED headlights need constant current supplied, not pulse power supplied from this kind of intermittent power supply system. Installing LED headlights into a vehicle with PWM configurations will result in flashing bulbs or bulbs that turn off after a few minutes. In this situation, a PWM module is required. The module’s large capacitance will basically store up power to eliminate the pulse and supply to the LED headlights with a constant current.

3. Daytime Running Light (DRL)

Many vehicles operate their headlights at a lower voltage to act as a daytime running light and if you’re using aftermarket HID or LED headlight bulbs this can cause major issues!. The idea behind the DRL is a safety feature for daytime driving. It adds to the visibility of your vehicle for other drivers. A DRL is a light that is dimmer than your normal headlight operation and sometimes uses your headlight bulbs to function. It does this by dimming the original halogen bulbs in a few different methods: 1: Dimming by resistance. If you have a resistance DRL (like many Subaru vehicles) a lot of times you can unhook the DRL resistor module and completely bypass your DRL system. 2: Dimming by PWM. If the vehicle uses a PWM circuit to dim your lights for a DRL function it means it’s flashing voltage to the light bulb circuit so fast that it dims the halogen bulb but the flashes are still too quick to be visible by the human eye. You solve this type of DRL problem with a PWM module. 3: Dimming by voltage reduction. If your vehicle simply steps down the voltage from 12v dc to 6v, 7v, or 9v dc, you have 2 options: Either get a LED headlight bulb designed to function at these levels, or install a relay harness that will give your bulbs full brightness during the DRL phase.

Recent Blog

-

-

-

2022-12-23What is Plug and Play LED Lighting?

2022-12-23What is Plug and Play LED Lighting? -

-

-

-

2022-12-045 Easy Ways to Fixing Your Broken LED Lights

2022-12-045 Easy Ways to Fixing Your Broken LED Lights -

-

2022-11-30Does CAN Bus work with LED headlights?

2022-11-30Does CAN Bus work with LED headlights? -

2022-11-2910 LED Headlight Advantages You Need to Know

2022-11-2910 LED Headlight Advantages You Need to Know -

-

-

-

-

-

-

-

-

2023-10-26China 134TH Canton Fair 2023

-

2023-04-24Automec 2023: SK Lights Up São Paulo Expo

-