A Brief Guide on Understanding LED Headlight Beam Pattern for Your Car Headlights

A Brief Guide on Understanding LED Headlight Beam Pattern for Your Car Headlights

Overview

We all are aware of the fact that night drive accidents mostly occur due to reasons like stress, alcohol, and so on. But, did you know that high flashing LED headlights can make the driver go almost blind leading to substantial loss? Hence, LED headlight beam patterns are vital for safe driving so that no glares and high flashes of light are there.

It is extremely important to get quality LED headlights for your vehicles. In this article, we are going to explore a lot more about the light beam pattern for cars – a brief yet detailed guide.

Keep reading to explore more about what is a good headlight beam pattern, how to adjust the headlight beam pattern, and much more.

What is an LED Headlight Beam Pattern?

An LED headlight beam pattern is the pattern made by the light emitted from the LED headlight lamps. The headlight beam pattern depends upon the position of the LED headlight lumps whether the emission of lights is broader and wider or the opposite.

The light generates from the headlight housing, the headlight lens, the bulb itself, or either from all of them. The change of equipment for automotive vehicles or LED headlights from OEM affects the beam pattern of headlights and the way they reflect on the roads.

5 Factors That Affect The LED Headlight Beam Pattern

Before we dig deeper about adjusting the headlight beam pattern, there are five factors that affect the pattern. Hence, producing an extra glaring beam pattern of LED headlights. Let’s get into it.

- Car headlight housing

- LED Chips

- The Arrangement of Headlamp Beads

- LED Spacing

- LED Headlight Bulb Installation

Car Headlight Housing

Car headlight housing has two more kinds i.e., projector headlight housing and reflector headlight housing.

As we are evolving in technology, there are different LED headlight assemblies and different patterns of LED headlights. Therefore, their installation is different and requires scrutiny.

Projector Headlight bulbs and Project Headlight Beam Pattern

The projector headlight, are high-energy and high-performance headlight bulbs that used to be available only for luxury cars. Projector headlights have a magnifying glass that has high brightness due to their property of high-intensity discharge (HID) and light-emitting diode (LED) bulbs. Therefore, projector LED headlight bulbs should not be used with traditional reflectors.

Since projector headlight bulbs have HID and LED, they produce a bright LED headlight beam pattern at a greater distance where the light is needed and less at the sides of the headlight.

For the installation of the projector headlights, there is a cutoff shield. The purpose of the cutoff shield is to aim the headlight beam patterns downwards – on the road. Hence, the emission of LED headlight beam patterns does not produce blinding lights.

Reflector Headlights and Headlight Beam Pattern

Reflector headlight bulbs are the traditional bulbs that are usually used in cars. Such bulbs produce light from the cluster of small bulbs placed in the middle of the headlight bulb.

Reflector headlights are budget-friendly since the product or manufacturing cost is not as high as the project headlight bulb. The reflector headlights emit light in the form of clusters. Therefore, when the light is produced it produces glare.

Therefore, in order to avoid the production of glare, the project headlight housing is better and more effective in results.

LED Chips

LED Chips are of different kinds and their manufacturing varies in their different types. Different types of LED headlight bulb chips produce different headlight beam patterns. If you want to know more about LED chips, then read our previous article on Three Different types of chips and their advantages.

The two most common used LED chips in the automotive LED headlight bulbs are:

Chip on Board (COB)

Chip on board LED chipsets to belong to the first generation of LED Headlight bulbs. They fall in the affordable price range yet produce enough brightness. The application of LED headlight bulbs that use COB is usually towards the lower end.

As far as the beam pattern headlight is concerned, Chip on Board produces uniform illumination. But when it comes to the headlight beam pattern, it is poor and diffuses the light concentration.

Flip Chip

These type of chips have made their place in the market as they are high-performance in terms of light distribution and LED beam pattern. Flip chips also have a cutoff shield which makes the light distribution even and uniform with a concentrated amount of light.

Arrangement of headlight Beads

We have been talking about LED headlight lamps, but this time we are going to focus on LED headlight beds. The LED headlight beads are the core part of the LED chips and different chips have different light distribution.

Let’s talk about the flip chips for LED headlight bulbs. Flip hips have rectangular-shaped headlight beads, and they perform wider light beam patterns.

Some LED beads are square and this array of beads is intended to spread the light of the focused beam pattern, especially at night times.

At SK LED Tech, you can check A12s and K12Max for the best LED headlight experience with high power and energy efficiency that gives an amazing laminating beam pattern with no glare and dark spots.

LED Spacing

For LED spacing, the width adjustment with filament and thickness of the headlight matter.

When adjusting LED headlights, the spacing between each headlight should be as close as the width of the original filament.

Avoid having multi-sided LED headlight bulbs or LED headlight bulbs with thick substrates because they have multiple light points and do not produce a focused and even beam pattern.

LED headlight Bulbs Installation

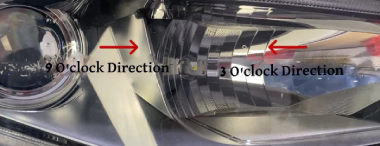

Installing LED headlight bulbs is extremely important to obtain the right LED headlight beam pattern. If you install the headlight bulbs upside down, then light distribution will result in poor lightning. The proper way to adjust the LED headlight bulbs is to set them at 3 O’clock and 9 O’clock directions while diodes are in opposite directions to each other.

How To Adjust The Headlight Beam Pattern To Attain Perfect Light Beam Pattern?

An important factor to note is that LED headlight bulbs have different optical designs. Every headlight bulb must be positioned keeping in the optical design of the headlight bulb.

Single Chip Filament LED Headlight Bulb Adjustment

If you are installing a LED headlight bulb with a single chip filament, then adjust it in a side-to-side position or orientation. This entails that one side of the LED should face in a 3 O’clock direction and the other side should face 9’O clock direction. Following these directions would help the LED headlight bulb to emit the LED headlight beam pattern at an angle of 360 degrees. Hence, light distribution will be equal, and even – producing concentrated light. Now, this might look like a puzzle to you – see the picture below for a better understanding.

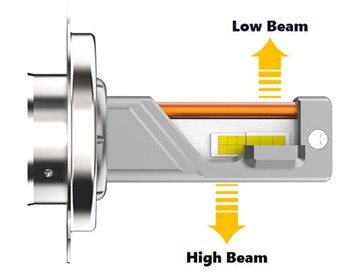

Dual Beam LED headlight Bulbs

Dual-beam LED headlight bulbs are those bulbs that have two diodes installed in them. The position of each diode is one slightly above the other and together they produce both high and low light beam diodes in the bulb.

For installing dual beam headlight bulbs, the diode with high light intensity is atop the diode with lower beam light. In addition to that, the dual-beam headlight bulbs have a shield ensuring that the LED headlight beam pattern direction is at the right angle.

Adjusting the LED headlight bulbs in an upside-down direction is outrightly dangerous and highly not recommended.

To adjust the LED headlight is one of the most crucial tasks. Adjusting the headlight beam pattern correctly ensures safe driving and appropriate emission of lights from the headlight bulbs producing the perfect light beam pattern. LED headlight bulbs with flip-chip also have a cutoff shield that ensures coherent light production.

Bottom line

LED headlight beam pattern is the factor that determines your driving experience.

For a better driving experience every time, and safe driving at night, the headlight beam pattern and LED headlights are integral.

At, SKLED tech, we have a range of LED Headlight bulbs that are specially made to be the source of an even LED beam pattern.

Head over to our LED headlight bulbs to see our latest products manufactured and boarded in the store.

OR

Get a free quote now.